The BIOvator® is a combination of a device and a process — targeting the quickest transformation of organic matter into consistent – quality compost at the lowest possible cost and management effort.

What is BIOvator?

The #1 Name for In-Vessel Composting

Let the revolutionary BIOvator® help you regain control of organic waste and mortality management.

Since it’s introduction to the market in 2004, the BIOvator® in-vessel composter has become a widely recognized product of choice for organic waste and animal mortality management. For good reason: incineration is costly and high-maintenance, rendering carries environmental and regulatory risk, and compost buildings require intensive labour and use of space.

The BIOvator® provides a cost-efficient and environmentally responsible solution to organic waste management. Virtually eliminating biosecurity risks of mortality management and reduces many of the concerns associated with more traditional methods of disposal.

BIOvator® – the only name you want

The BIOvator® is the only all-stainless steel, in-vessel composter on the market in successful operation in more than 1000 locations Worldwide. Free of any plastic drum material that can warp and wear. The BIOvator® has been strategically engineered with stainless steel and has been tested for unmatched durability and function.

History

The BIOvator® was the brainchild of the R&D staff of a large Southeastern Manitoba livestock integrator. Mortality disposal has always been a challenge for livestock producers, and rendering has historically been the option of choice. With bio-security issues on the rise and the cost of transport becoming an economic issue, the integrator set out to find an alternative.

At the time there were three options other than rendering to consider. These three options were: Burial, Incineration and Cell Composters. Burial was not practical due to the size of their operations and the hard ground experienced in winter. Incineration was not considered because of the on going costs and maintenance concerns. They started to use four celled compost bunkers. Although cell composting worked, it was felt there must be a better way.

In January 2001 a project began to find a cost effective, technically sound and user friendly system for composting. The result was the BIOvator®.

The BIOvator® was developed after extensive research and development work that was conducted. The main objective of the R&D work was to “development of a cost-effective alternative to the outdoor composting process”. A variety of different drum materials and sizes were tested over a two year period with the product of choice being a 4’ diameter all steel vessel. The 4 foot diameter provided the most uniform product mix resulting in a preferred end product, and the all steel construction was chosen for its superior durability and integrity.

The BIOvator® is a combination of a device and a process - targeting the quickest transformation of animal carcasses into consistent quality compost at the lowest possible cost and management effort.

With its successful implementation into the production system, the BIOvator® was introduced to the market in 2004. In 2005, the BIOvator® was successfully introduced into the poultry industry, and the slaughterhouse industry shortly after. BIOvator® has undergone continual testing in various organic disposal markets, and is currently being employed in the agricultural, municipal and industrial markets to handle organic wastes of all nature.

Nioex Systems Inc. acquired the rights to the BIOvator® products in October 2008 to be their flagship product in their pursuit to provide environmentally and socially acceptable solutions to the organic waste industries.

Today Nioex continues to R&D and develop the product. During the past number of years, a variety of in-vessel composter sizes have been made available to suit all applications. In 2017 Nioex added the optional remote-control hydraulic door to it’s BIOvator® offering. In 2019, the BIO5544 was introduced, this is a large capacity in-vessel composter to suit large operations that comes standard with remote control hydraulic door, stainless-steel inner drum and stainless-steel shell. This unit as its predecessors has the most robust drum, frame and drive system offered.

Today BIOvator® is owned by a company with more than 40 years of experience in the metal fabrication industry. The R&D, design and manufacturing is all in-house, within our group with over 15 engineers and designers.

Specifications

The BIOvator® is a patented all-steel design, ensuring optimal functionality and longevity. An ideal combination of carbon and stainless steel make it a durable and affordable investment.

Our current BIOvator® models have the capacity to handle up to 1500 lbs. of organic waste or mortality per day, requiring only .05 ft3 of shavings per each pound of waste. This amounts to approximately 10,500 lbs. per week, or 547,500 lbs. of organic waste per year. And with the option of having multiple units on a site, our BIOvator® models can handle any amount of organic waste.

3 ft diameter x 8-16 ft long insulated vessel with stainless steel shell and Stainless Steel inner drum

4 ft diameter x 18-42 ft long insulated vessel with stainless steel shell and Stainless Steel inner drum, other sizes available.

5.5 ft diameter x 44 ft long insulated vessel with stainless steel shell and Stainless Steel inner drum

Two loading doors 7.5’ x 2’, inspection openings and one 18” discharge opening.

Stainless steel paddles mounted on the inside vessel walls.

Optional Galvanized steel frame, with heavy-duty nylon rollers supporting the vessel.

Driving system: 1 - 2 hp motor – 110 V, 2 gear boxes, heavy duty bearing, sprocket and chain. 220 V available

Comes standard with Stainless Steel inner drum

Optional Remote Controlled hydraulic door option 4′ and 5.5′ units

Optional Bone Screener

Turns deads into dirt

BIOvator Models

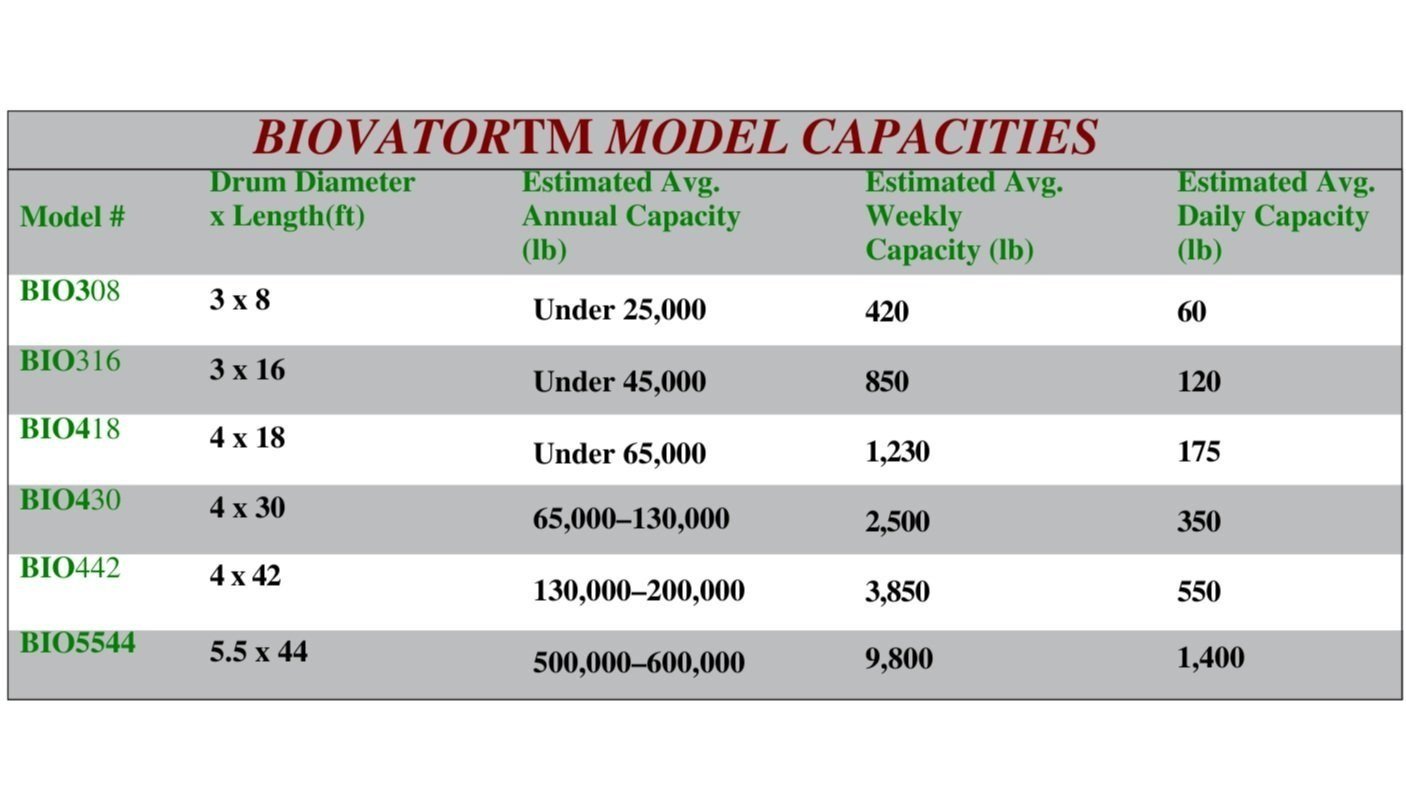

With six models to choose from, there is guaranteed to be a BIOvator® perfect for your size of operation.

BIO308

-

3 x 8 ft

-

Daily: 60lbs

Weekly: 420lbs

Annual: Under 25,000lbs

BIO316

-

3 x 16 ft

-

Daily: 120lbs

Weekly: 850lbs

Annual: Under 45,000lbs

BIO418

-

4 x 18 ft

-

Daily: 175lbs

Weekly: 1,230lbs

Annual: Under 65,000lbs

BIO430

-

4 x 30 ft

-

Daily: 350lbs

Weekly: 2,500lbs

Annual: 65,000-130,000lbs

BIO442

-

4 x 42 ft

-

Daily: 550lbs

Weekly: 3,850lbs

Annual: 130,000-200,000lbs

BIO5544

-

5.5 x 44 ft

-

Daily: 1,400lbs

Weekly: 9,800lbs

Annual: 500,000-600,000lbs